Innovation Drives the Future: How a Chinese Precision Ceramic Manufacturer Leads Global Industrial Transformation with Cutting-Edge Materials

In today's rapidly advancing manufacturing sector, precision ceramic materials have become a core engine driving innovation across numerous industries. Jinhua Deyu Precision Ceramic Technology Co., Ltd. from China, leveraging its profound expertise in key materials such as alumina, zirconia, silicon carbide, and silicon nitride, has successfully extended its solutions to markets in Southeast Asia and Europe, establishing itself as a trusted partner in the global industrial chain. This case study delves into how Deyu Company has overcome challenges and earned global trust by centering its strategy on material technology.

I. Market Challenges and Strategic Positioning: Addressing Global Demands with Material Science

As manufacturing in Southeast Asia upgrades and Europe increasingly pursues high-performance, sustainable solutions, the market imposes near-stringent requirements for components capable of withstanding high temperatures, wear, corrosion, and maintaining high precision. Traditional metal materials often fall short under extreme operating conditions.

Deyu Company accurately identified this trend, focusing its strategic core on the research, development, and application of advanced precision ceramic materials. The company understands that fundamental solutions for industries ranging from semiconductors—which demand high hardness and insulation—to energy and chemical processing—which require ultimate heat and chemical stability—lie within the microstructure of materials like alumina, aluminum nitride, and silicon carbide. Consequently, Deyu has adopted a "Materials Lead, Customization Drives" strategy, aiming to provide customers with integrated component solutions based on the most suitable materials, rather than single products.

II. Core Technological Breakthroughs: Building a Comprehensive Precision Ceramic Material Matrix

Deyu's core competitiveness is built upon the optimal application and innovative use of its key material matrix.

Diversified Material Platform: Deyu has established an extensive material system. Alumina ceramics, known for their excellent insulation, wear resistance, and cost-effectiveness, serve as the foundation for electronic substrates and wear-resistant parts. Zirconia, prized for its high toughness, strength, and biocompatibility, excels in medical devices and precision cutting tools. Meanwhile, silicon carbide and silicon nitride ceramics have become irreplaceable in aerospace, new energy vehicles, and high-end thermal processing equipment due to their exceptional high-temperature resistance, corrosion resistance, and low thermal expansion. To address high thermal conductivity needs, Deyu's aluminum nitride substrate products successfully resolve heat dissipation challenges in power electronic devices.

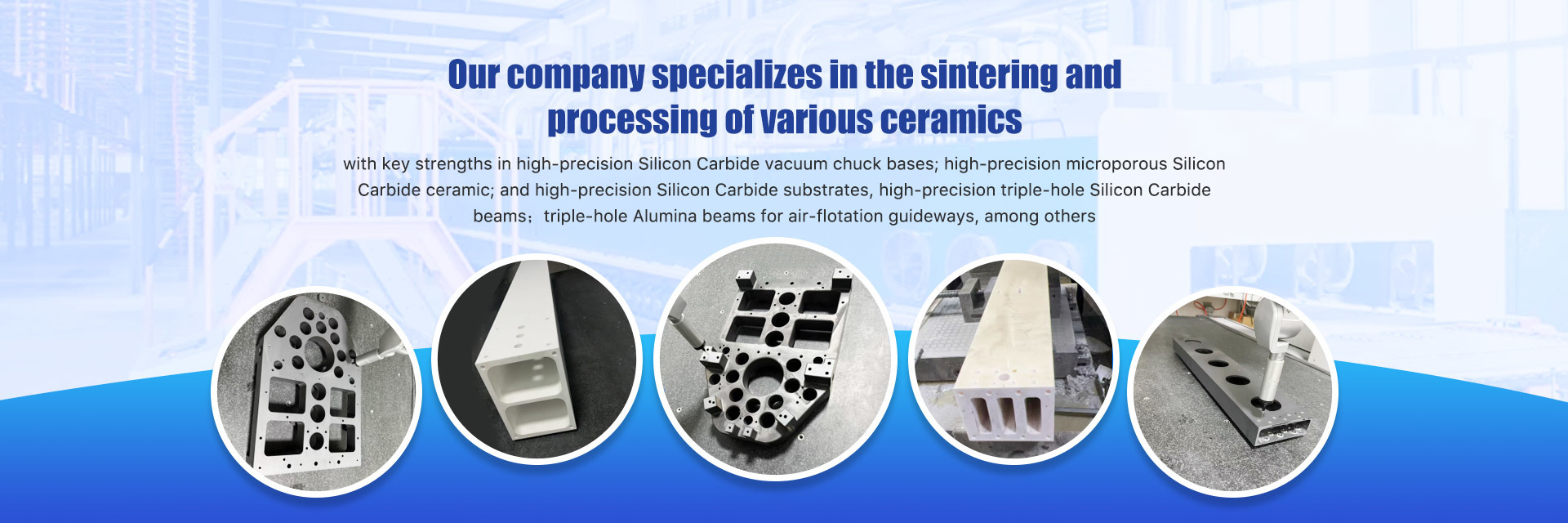

Precision Manufacturing and Processing Technology: Deyu possesses full-chain capabilities, from powder preparation and near-net-shape forming to ultra-precision machining. Particularly in the sintering technology for complex-shaped silicon carbide and silicon nitride components, as well as the nanoscale surface polishing of zirconia ceramics, Deyu has achieved industry-leading standards, ensuring stable product performance even in extreme environments.

III. Global Application Cases: Remarkable Achievements from Southeast Asia to Europe

Case 1: Driving Automotive Industry Upgrading in Southeast Asia

A well-known automotive parts manufacturer in Thailand faced efficiency bottlenecks with metal materials in its turbocharger rotors. Deyu Company developed customized silicon nitride ceramic rotor balls for them. Thanks to the lightweight, high-temperature resistance, and self-lubricating properties of silicon nitride, rotor speed significantly increased, greatly improving engine efficiency while reducing fuel consumption and emissions. This project established Deyu as a strategic supplier of advanced materials for this Southeast Asian industry giant.

Case 2: Breaking Barriers in European Semiconductor Equipment

A German semiconductor equipment manufacturer required a chamber lining material capable of withstanding plasma corrosion while maintaining extremely high dimensional stability. Deyu's ultra-high-purity alumina and aluminum nitride composite ceramic solution perfectly met this need. In particular, the high thermal conductivity of aluminum nitride effectively protected sensitive components, ensuring uniformity and yield in the chip manufacturing process, earning high recognition from this renowned European client known for its rigorous standards.

Case 3: Innovating with European New Energy Enterprises

In collaboration with a Dutch hydrogen energy company, Deyu developed key sealing and insulating components for their proton exchange membrane electrolyzers. This application required materials to withstand long-term exposure to strong acid corrosion and high voltage potential differences. Deyu recommended and optimized a high-density zirconia ceramic solution, whose exceptional chemical inertness and insulating properties ensured the long-term, safe, and efficient operation of the electrolyzers, advancing clean energy technology.

IV. Key Success Factors and Future Outlook

Deyu Precision Ceramics' global success stems from several key factors: a profound understanding of the performance of core materials, including alumina, silicon carbide, silicon nitride, zirconia, and aluminum nitride; the ability to accurately select materials based on specific application scenarios (e.g., wear resistance, corrosion resistance, thermal conductivity, insulation); and a consistently "customer-operating-condition-oriented" customized engineering service.

Looking ahead, Deyu Company will continue to deepen its research and development in ultra-high-performance materials like silicon carbide and silicon nitride, expanding into cutting-edge markets such as third-generation semiconductors, aerospace, and biomedical applications. The company is committed to working with global partners to continuously shape a more efficient, reliable, and sustainable industrial future through innovative precision ceramic material solutions.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!